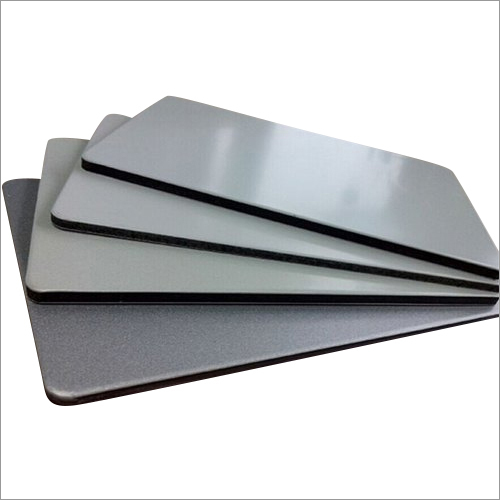

4 mm Aluminum Composite Panel

Price 70 INR/ Square Foot

4 mm Aluminum Composite Panel Specification

- Usage

- Building Facade, Cladding

- Protective Film

- Yes, PE Protective Film

- Feature

- Weather Resistant, Lightweight, High Durability

- Material

- Aluminum

- Dimension (L*W*H)

- 2440 mm x 1220 mm x 4 mm

- Surface Treatment

- PVDF Coated

- Coating Thickness

- 25 microns (PVDF coating)

- Panel Thickness

- 4 mm

- Aluminum Thickness

- 0.30 mm

- Tensile Strength

- 130 MPa

- Yield Strength

- 110 MPa

- Color

- Grey

- Application

- Exterior

4 mm Aluminum Composite Panel Trade Information

- Minimum Order Quantity

- 160 Square Foots

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 5-7 Days

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Africa, Central America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About 4 mm Aluminum Composite Panel

Product Details:

| Available Length | 4880 mm |

| Available Width | 1550 mm |

| Material | Aluminium |

| Brand | Alstrom International Private Limited |

| Grade | Exterior/ Interior |

| Model Name/Number | ACP-10 |

| Thickness | 4 mm |

| Usage/Application | Construction |

Exceptional Durability and Strength

Engineered for longevity, this aluminum composite panel offers high tensile and yield strength, making it highly resistant to impact and shattering. The aluminum faces are bonded with superior strength above 135 N/mm, ensuring stability and performance in demanding environments.

Versatile Weather-Resistant Solution

Designed for outdoor use, these panels maintain their integrity and appearance in temperatures from -50C to +80C. The PVDF coating provides robust protection against harsh weather, UV exposure, and chemical aggression, ideal for building exteriors and cladding projects.

Flexible Application and Protective Features

With a choice of matt or glossy grey finishes and a PE protective film, these panels accommodate diverse design requirements. Their lightweight composition makes installation straightforward, while the non-toxic LDPE core enhances fire resistance and overall safety.

FAQs of 4 mm Aluminum Composite Panel:

Q: How can the 4 mm Aluminum Composite Panel be used in building applications?

A: This panel is primarily employed for exterior cladding, building facades, and architectural features. Its lightweight and robust construction make it easy to install while providing long-term protection and aesthetics for various structures.Q: What are the advantages of the PVDF-coated surface on this panel?

A: The PVDF coating delivers superior weather and chemical resistance, guarding against acids, alkalis, and UV damage. It ensures the panel maintains its color, gloss, and integrity even in harsh outdoor conditions.Q: When is it advisable to choose the optional A2 fire resistance grade?

A: Opt for the A2 fire resistance option in projects requiring higher fire safety standards, such as high-rise buildings, public infrastructure, or stringent regulatory environments. This upgrade enhances the panels fire-retardant properties.Q: Where are these aluminum composite panels most effectively installed?

A: They are most effective in exterior settingson building facades, wall cladding, and envelope structureswhere their weather resistance, lightweight nature, and durability offer significant benefits over traditional materials.Q: What is the installation process for the 4 mm aluminum composite panel?

A: Panels are typically affixed using mechanical fasteners or gluing systems suitable for the substrate. Their manageable size and weight facilitate rapid installation, and the PE protective film helps prevent surface scratches during handling.Q: How does the non-toxic LDPE core benefit building safety and the environment?

A: The use of a non-toxic LDPE plastic core ensures that the panel is safe for occupants and does not release harmful substances, thereby supporting environmentally conscious construction practices.Q: What makes these panels advantageous for facade and cladding projects in India?

A: Withstand extreme temperatures, offer high impact resistance, and feature a lightweight profile, making them ideal for Indias varied climates and diverse architectural needs for both new construction and renovation projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

Road Signage Aluminium Composite Panel

Price 52 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Protective Film : Polyethylene Protective Film

Application : Advertising

Feature : Other, Weather Resistant, UV Resistant, Corrosion Resistant

Tensile Strength : >46 MPa

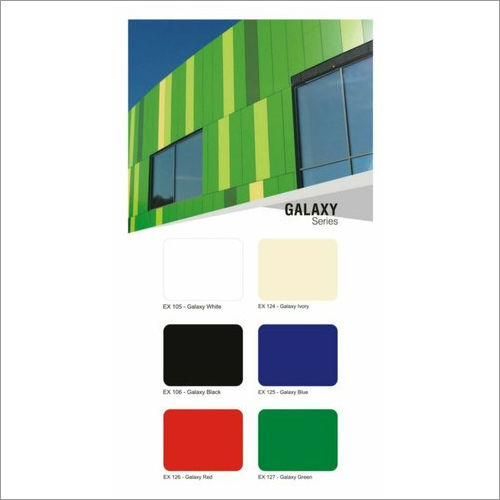

Galaxy Sparkle Aluminum Composite Panel

Price 120 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Protective Film : PE protection film (removable)

Application : Exterior

Feature : Other, Sparkle finish, Weatherresistant, Lightweight, Durable, Fire retardant

Tensile Strength : 130 MPa

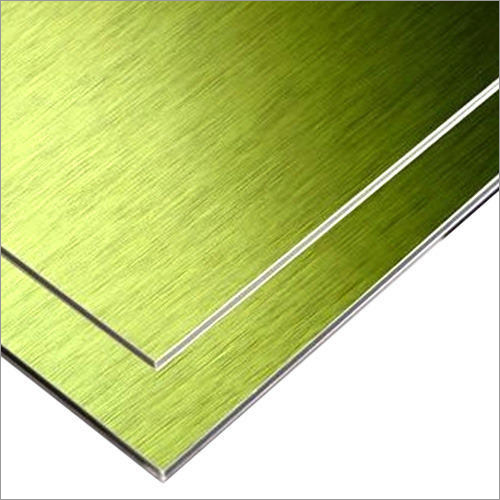

Brush Aluminium Composite Panel

Price 70 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Protective Film : Two side PE Protective film

Application : Exterior

Feature : Other, Weather Resistant, Corrosion Resistant, Easy to Install

Tensile Strength : 33 MPa

Customized Aluminum Composite Panel

Price 70 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Protective Film : PE Film on Surface

Application : Exterior

Feature : Other, Weather Resistant, Durable, Lightweight, Corrosion Resistant

Tensile Strength : 130 MPa

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS