4 Mm Polyester Aluminium Composite Panel

Price 70 INR/ Square Foot

4 Mm Polyester Aluminium Composite Panel Specification

- Protective Film

- Self-adhesive PE film on surface

- Usage

- Cladding, Facades, Signage

- Feature

- Weather-resistant, Durable, Lightweight, UV Resistant

- Material

- Aluminum

- Dimension (L*W*H)

- 1220 mm x 2440 mm x 4 mm

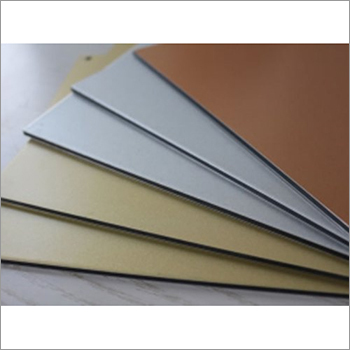

- Surface Treatment

- Polyester Coating

- Coating Thickness

- 16-20 microns (polyester)

- Panel Thickness

- 4 mm

- Aluminum Thickness

- 0.18-0.30 mm (per skin)

- Tensile Strength

- 55 MPa

- Yield Strength

- 55 MPa

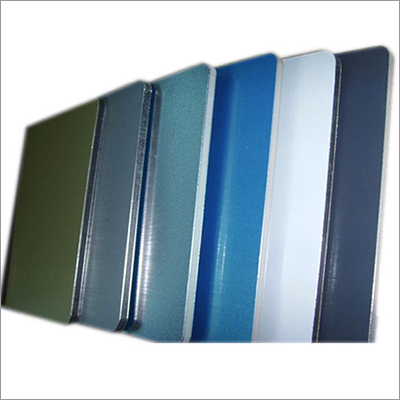

- Color

- Silver/Grey (custom colors available)

- Application

- Exterior

4 Mm Polyester Aluminium Composite Panel Trade Information

- Minimum Order Quantity

- 160 Square Foots

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 5-7 Days

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Central America, Africa, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About 4 Mm Polyester Aluminium Composite Panel

With an aim to become a pioneer in this domain, we are offering a unique range of 4 Mm Polyester Aluminium Composite Panel. It a panel which is coated with a layer of aluminium to obtain a highly insulated flat panel. Additionally, provided panel is ideal for exterior wall cladding applications. 4 Mm Polyester Aluminium Composite Panel is widely demanded across the commercial sector due to its sunlight resistant, abrasion-resistant and maintain high colour retention.

Product Details:

| Boiling Water Resistance | 2 hours without change |

| Paint Thickness | 21-23 micron |

| Panel Diagonal Tolerance | +/-5 mm |

| Panel Length Tolerance | +/-3 mm |

| Panel Thickness Tolerance | +/-0.2 mm |

| Panel Weight | 4.8 kg/m2 |

| Panel Width Tolerance | +/-2 mm |

| Material | Aluminium |

| Brand | Alstrom International Private Limited |

| Temperature Resistance | -50 deg C to +90 deg C |

| Thickness | 4 mm |

| Usage/Application | Exterior |

Superior Weather Resistance

Engineered to perform reliably in diverse environmental conditions, this composite panel withstands extreme temperatures ranging from -50C to +80C. Its weather-resistant and UV-resistant properties ensure long-lasting performance, making it an excellent choice for demanding exterior applications.

Customizable Surface and Colors

Available in smooth, high gloss, or matte finishes, our panels also offer a range of standard and custom colors to fulfill design requirements. The self-adhesive PE protective film keeps surfaces pristine during installation and transportation.

Lightweight Yet Durable Construction

Despite its robust build, the panel remains lightweight at approximately 5.5 kg/m. The aluminum layers (0.18-0.30 mm per skin) combined with a non-toxic LDPE core deliver exceptional strength and easy handling, offering long-term durability without extra weight.

FAQs of 4 Mm Polyester Aluminium Composite Panel:

Q: How is the 4 mm Polyester Aluminium Composite Panel installed for cladding or faade applications?

A: The panels are designed for ease of installation, suitable for mechanical fixing with a subframe on building exteriors. Edge banding can be provided upon request for a finished look, and panels feature a self-adhesive PE protective film to prevent surface damage during handling and installation.Q: What makes the LDPE core material safe and reliable for construction?

A: The core consists of non-toxic low-density polyethylene (LDPE), offering excellent moisture resistance and durability. Customers can also opt for a fire-retardant (FR) core for enhanced safety and compliance with Class B1 fire rating standards.Q: When should I consider using a polyester-coated aluminum composite panel over other types?

A: Polyester-coated panels are highly suited for exterior applications such as facades, signage, and cladding, especially where UV resistance, lightweight structure, and customizable aesthetics are key priorities. Their robust coating ensures long-term color retention and surface integrity.Q: Where can these panels be applied beyond building facades?

A: Besides building facades, these aluminum composite panels are commonly used in outdoor signage, advertising boards, and protective coverings in commercial, retail, and institutional settings due to their durability and sleek appearance.Q: What processing methods are recommended for cutting or shaping these panels?

A: Panels can be machined, cut, or routed using standard aluminum-working tools. They maintain dimensional stability and surface finish during processing, ensuring precise fits and smooth visuals for a variety of architectural designs.Q: What are the main benefits of choosing this composite panel for construction projects?

A: The key benefits include lightweight yet strong construction, exceptional weather and UV resistance, customizable colors and finishes, excellent moisture resistance, and straightforward installation, making them ideal for both functional and aesthetic needs in exterior building projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

Nano Coating Aluminum Composite Panel

Price 130 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Panel Thickness : 4 mm

Tensile Strength : 46 MPa

Yield Strength : 44 MPa

Usage : Other, Wall Cladding, Building Facades

PVDF Aluminum Composite Panel

Price 75 INR / Square Foot

Minimum Order Quantity : 01 Square Foot

Panel Thickness : 4 mm

Tensile Strength : 33 MPa

Yield Strength : 44 MPa

Usage : Other, Cladding, Facade, Signage

Wood Grain Aluminum Composite Panel

Price 65 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Panel Thickness : 3mm, 4mm, 5mm, 6mm (customized available)

Tensile Strength : 110 MPa

Yield Strength : 80 MPa

Usage : Other, Wall Cladding, Facades, Signage, Interior and Exterior Decoration

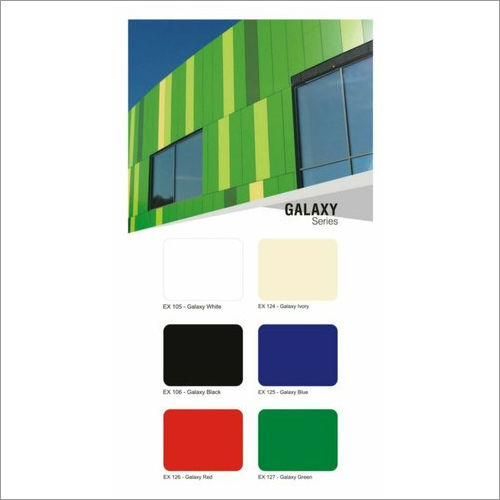

Galaxy Sparkle Aluminum Composite Panel

Price 120 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Panel Thickness : 3 mm, 4 mm, 6 mm (customizable)

Tensile Strength : 130 MPa

Yield Strength : 80 MPa

Usage : Other, Building cladding, Facade panels

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS