ATM Polyester Aluminum Composite Panel

Price 53 INR/ Square Foot

ATM Polyester Aluminum Composite Panel Specification

- Protective Film

- Transparent PE Film, Removable

- Usage

- Cladding, Facade, Signage, Curtain Walls

- Feature

- Lightweight, Weather Resistant, Rigid

- Material

- Aluminum

- Dimension (L*W*H)

- 1220 mm x 2440 mm x 4 mm

- Surface Treatment

- PVDF Coated

- Coating Thickness

- 18-25 micron

- Panel Thickness

- 3 mm, 4 mm, 6 mm

- Aluminum Thickness

- 0.12 mm to 0.50 mm

- Tensile Strength

- 24 MPa

- Yield Strength

- 110 MPa

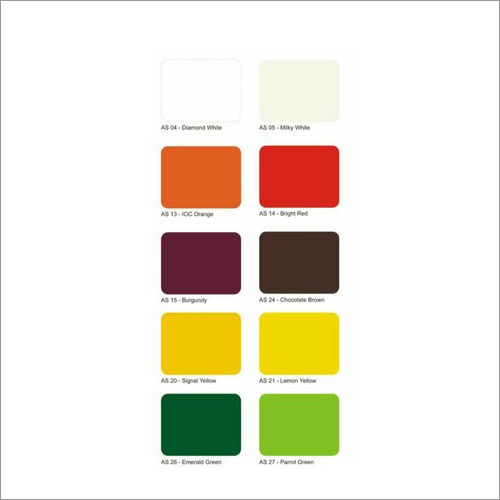

- Color

- Multiple Colors Available

- Application

- Exterior

- Flexural Strength

- 100 MPa

- Core Material

- Polyethylene (PE)

- Fire Rating

- Self-extinguishing, as per ASTM E84

- Temperature Resistance

- -50C to +80C

- Water Absorption

- < 0.01%

- Gloss Level

- Matt, Glossy, High Gloss

- Adhesive Type

- High-Performance Adhesive

- Impact Resistance

- High

- Standard

- ASTM, EN, GB

ATM Polyester Aluminum Composite Panel Trade Information

- Minimum Order Quantity

- 160 Square Foots

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 5-7 Days

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, North America, Africa

- Main Domestic Market

- All India

About ATM Polyester Aluminum Composite Panel

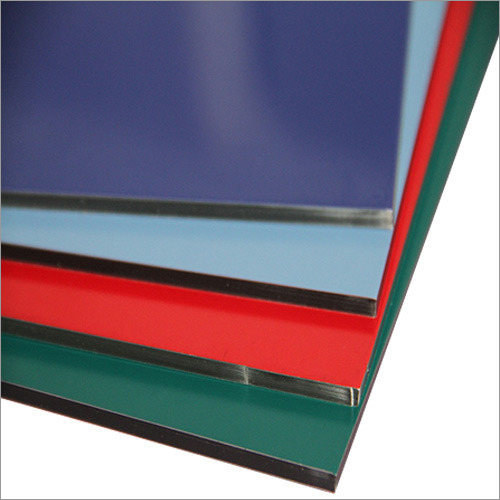

With the support of vast infrastructure, we are involved in developing highly demanded ATM Polyester Aluminum Composite Panel. It is featured for its weather resistance, strength and fire resistance. Apart from this, provided panel is formed through continuous hot-pressing in one production line. ATM Polyester Aluminum Composite Panel is used for external cladding, signage and other applications. It is a panel which can withstand temperature extremes. It is made from aluminium composite panels to ensure thermal insulation qualities.

Product Details:

| Thickness Tolerance | +/- 0.02 mm |

| Material | ACP |

| Size | 8 X 4 ft |

| Brand | Alstrom International Private Limited |

| Grade | Interior |

| Temperature Resistance | -50 Degree to + 90 Degree C |

| Thickness | 3 mm |

| Shape | Rectangular |

| Weight | 2.9 Kg |

| Usage/Application | Exterior |

Engineered for Versatile Applications

ATM Polyester Aluminum Composite Panels are specifically crafted for demanding exterior environments. Their unique combination of polyethylene core and aluminum surface, enhanced with PVDF coating, results in a panel that is both lightweight and rigid, suitable for cladding, decorative facades, curtain walls, and commercial signage. The panels are offered in a wide spectrum of colors and gloss levels to match various design requirements.

Durability Meets Performance

Built to outlast harsh environments, these panels offer high impact resistance and can tolerate temperature fluctuations from -50C up to +80C. The PVDF surface treatment ensures long-lasting gloss and color stability, while the panels stay resistant to water absorption, maintaining structural integrity in wet conditions. High-performance adhesives and strict adherence to ASTM, EN, and GB standards guarantee reliability in all applications.

FAQs of ATM Polyester Aluminum Composite Panel:

Q: How do you install ATM Polyester Aluminum Composite Panels for exterior cladding or facades?

A: Installation typically involves fixing the panels onto a prepared framework using mechanical fasteners or specialized high-performance adhesives. Panels should be handled carefully to maintain the integrity of the protective PE film, which should only be removed after installation.Q: What are the main advantages of using these panels in architectural projects?

A: The panels are valued for their lightweight nature, high rigidity, and robust weather and impact resistance. Their fire-retardant properties as per ASTM E84, versatile appearance options, and long-lasting PVDF coating make them suitable for both aesthetic and protective architectural needs.Q: When is the best time to apply these panels during the construction process?

A: ATM Polyester Aluminum Composite Panels are typically installed after the main structural framework and insulation are complete, and just before final exterior finishes. This timing ensures optimal panel performance and integration with other faade systems.Q: Where can these panels be effectively used?

A: They are ideal for exterior applications including building cladding, curtain walls, signage, and decorative facades. Their durability and weather resistance make them suitable for commercial, industrial, and institutional buildings throughout India and beyond.Q: What process ensures the panels color and gloss longevity?

A: Each panel undergoes a precision PVDF surface coating process, ensuring resistance to UV rays, fading, and chemical exposure. This not only maintains gloss and color vibrancy but also protects the aluminum surface from environmental damage over time.Q: How do the panels benefit exterior architectural designs?

A: They offer a combination of aesthetic versatility, structural stability, and longevity. Their lightweight form simplifies handling, while consistent finish options and resistance to environmental stresses enhance overall building performance and appearance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

Gold Aluminium Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Application : Interior

Color : Gold

Material : Aluminum

Surface Treatment : PVDF Coated

Industrial PVDF Aluminum Composite Panel

Price 70 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Application : Exterior

Color : Grey

Material : Aluminum

Surface Treatment : PVDF Coated

Solid Aluminium Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Application : Interior and Exterior

Color : Silver, Grey, Custom colors available

Material : Aluminum

Surface Treatment : PE Coated

4 mm Aluminum Composite Panel

Price 70 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Application : Exterior

Color : Grey

Material : Aluminum

Surface Treatment : PVDF Coated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free