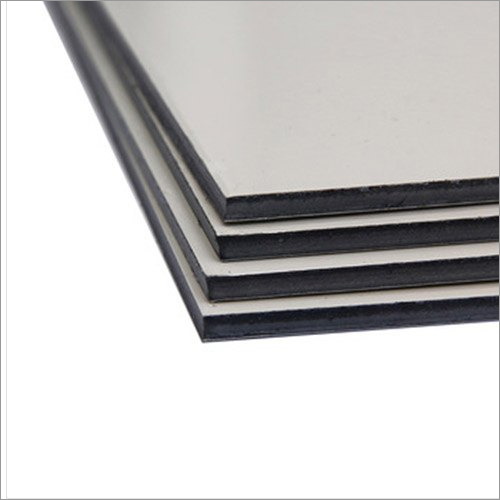

Industrial PVDF Aluminum Composite Panel

Price 70 INR/ Square Foot

Industrial PVDF Aluminum Composite Panel Specification

- Usage

- Building Facades, Wall Cladding, Signage

- Protective Film

- PE Protective Film on Surface

- Feature

- Weather Proof, UV Resistant, Fire Retardant

- Material

- Aluminum

- Dimension (L*W*H)

- 1220 mm x 2440 mm x Custom

- Surface Treatment

- PVDF Coated

- Coating Thickness

- 25 microns (PVDF)

- Panel Thickness

- 4 mm

- Aluminum Thickness

- 0.50 mm

- Tensile Strength

- 190 MPa

- Yield Strength

- 110 MPa

- Color

- Grey

- Application

- Exterior

Industrial PVDF Aluminum Composite Panel Trade Information

- Minimum Order Quantity

- 160 Square Foots

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 5-7 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About Industrial PVDF Aluminum Composite Panel

Product Details:

| Length | 2440 mm |

| Surface Finishing | Mirror Finish |

| Width | 120 mm |

| Usage | Exterior |

| Material | Aluminum |

| Brand | Alstrom International Private Limited |

| Thickness | 6 mm |

| Shape | Rectangular |

Advanced Weather and Fire Protection

Engineered to withstand severe environmental conditions, the panel features PVDF coating and a Class B1 fire resistance rating. Its non-toxic polyethylene core ensures safe installation in both public and private construction, while UV resistance and weatherproof properties maintain lasting performance outdoors.

Customizable Dimensions for Versatile Usage

Available in a standard size of 1220 mm x 2440 mm with a 4 mm panel thickness, these composite panels can be tailored in length and width up to 1550 mm. This adaptability makes them a preferred choice for diverse applications such as building exteriors, wall cladding, and commercial signage.

FAQs of Industrial PVDF Aluminum Composite Panel:

Q: How is the Industrial PVDF Aluminum Composite Panel installed in building projects?

A: These panels can be mounted using traditional cladding systems, which typically involve mechanical fasteners or adhesive bonding. The high-strength bonding film ensures secure attachment to substructures, making installation straightforward for experienced professionals.Q: What makes PVDF aluminum composite panels suitable for outdoor environments?

A: The PVDF coating offers exceptional weather resistance, UV protection, and color retention, making the panels ideal for building facades and outdoor signage exposed to harsh climates. The fire-retardant core provides additional safety for exterior applications.Q: When should custom sizing be considered for these panels?

A: Custom sizes should be specified when project designs demand dimensions different from the standard 1220 mm x 2440 mm format. With widths up to 1550 mm available, these panels accommodate special architectural requirements and unique project scopes.Q: Where are these composite panels commonly used?

A: They are widely used in commercial and industrial settings for exterior wall cladding, building facades, and signage. Their robust properties make them suitable for locations exposed to severe weather and high UV levels.Q: What is the application process for protective film on the panel surface?

A: A PE protective film is applied during manufacturing to safeguard the PVDF-coated surface from scratches and contamination during handling and installation. This film should be removed once installation is completed.Q: How does the panel benefit building owners and contractors?

A: Owners and contractors benefit from enhanced building durability, reduced maintenance costs, and improved fire safety. The customizable sizing, high tensile strength, and weatherproofing features deliver long-term reliability and architectural flexibility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

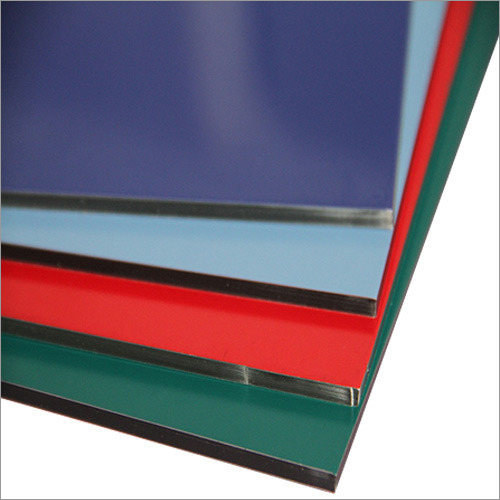

Fireproof Aluminum Composite Panel

Price 100 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Color : Multiple colors available

Panel Thickness : 4 mm (Standard)

Protective Film : PE Film (Removable)

Dimension (L*W*H) : 1220 mm x 2440 mm x (standard thickness)

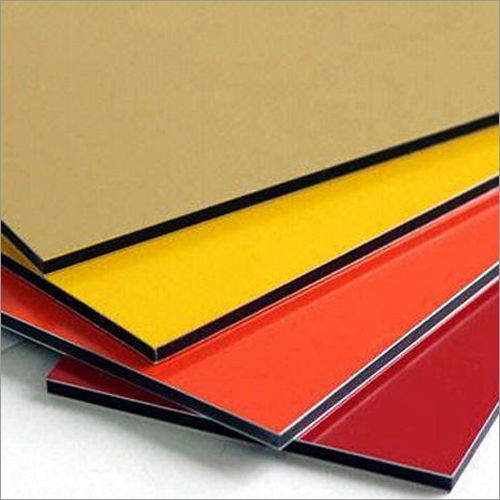

Metallic and Solid Aluminum Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Color : Metallic, Silver, Grey, Custom

Panel Thickness : 3 mm, 4 mm, 6 mm (customizable)

Protective Film : Single or doublesided, PEprotective film

Dimension (L*W*H) : 1220 mm x 2440 mm x (3 mm 6 mm)

Red Aluminum Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Color : Red

Panel Thickness : 3mm / 4mm / 5mm (customizable)

Protective Film : PE/PVC film on single or both sides

Dimension (L*W*H) : 1220mm x 2440mm x Custom

Nano PVDF Aluminium Composite Panel

Price 130 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Color : Customizable, Standard White/Silver/Grey

Panel Thickness : 4 mm

Protective Film : PE Protective Film on Surface

Dimension (L*W*H) : 1220 mm x 2440 mm x 4 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS