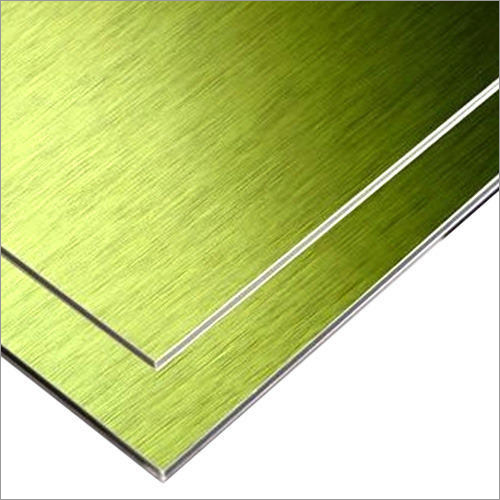

Brush Aluminium Composite Panel

Price 70 INR/ Square Foot

Brush Aluminium Composite Panel Specification

- Usage

- Building Cladding, Signage, Interior and Exterior Decoration

- Feature

- Weather Resistant, Corrosion Resistant, Easy to Install

- Protective Film

- Two side PE Protective film

- Material

- Aluminum

- Dimension (L*W*H)

- 1220 mm x 2440 mm x (as per requirement)

- Surface Treatment

- PVDF Coated

- Coating Thickness

- 25 Microns (PVDF Coating)

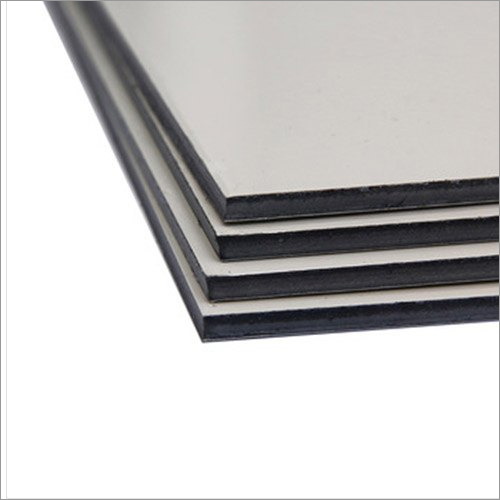

- Panel Thickness

- 3 mm, 4 mm, 5 mm (Standard)

- Aluminum Thickness

- 0.12 mm 0.50 mm

- Tensile Strength

- 33 MPa

- Yield Strength

- 110 MPa

- Color

- Silver, Champagne, Customized Brush Finish

- Application

- Exterior

- Sound Absorption

- 23 dB

- Width Tolerance

- ±2 mm

- Core Material

- Non-toxic Polyethylene

- Thermal Conductivity

- 0.45 W/m.K

- Standard Packaging

- Wooden Pallet, Wrapped with Protective Film

- Length Tolerance

- ±3 mm

- Gloss Level

- 20-40% (Matt Finish)

- Service Temperature

- -50°C to +80°C

- Fire Rating

- Class B1

Brush Aluminium Composite Panel Trade Information

- Minimum Order Quantity

- 160 Square Foots

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 5-7 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

About Brush Aluminium Composite Panel

Product Details:

| Surface Finishing | Polished |

| Color | Green |

| Material | Aluminum Alloy |

| Size | 12 X 4 ft |

| Brand | Alstrom International Private Limited |

| Composite Panel Type | Brush Finish |

| Thickness | 4 mm |

| Shape | Rectangular |

| Usage/Application | Interior |

High Fire Safety and Weather Resistance

With a Class B1 fire rating and excellent weather resistance, our Brush Aluminium Composite Panels are designed to protect buildings while maintaining visual appeal. The PVDF coating ensures longevity by guarding against harsh elements, making the panels suitable for both interior and exterior applications, including faades and commercial signage.

Precision Engineering and Durable Finishes

Manufactured to stringent tolerance standards (2 mm width, 3 mm length), each panel offers structural consistency and quality. The matt finish (20-40% gloss) and robust PVDF coating of 25 microns combine durability with modern aesthetics. The panels are available in multiple thicknesses and finishes, offering a customized solution for various architectural designs.

Easy Installation and Wide Application Range

Engineered for straightforward installation, the panels include protective PE film on both sides and are delivered on wooden pallets for easy handling. Their lightweight, yet robust design facilitates use in cladding, signage, and decorative projects, supported by the products strong tensile and yield strengths. Leading suppliers, exporters, and manufacturers across India ensure dependable supply and after-sales service.

FAQs of Brush Aluminium Composite Panel:

Q: How can Brush Aluminium Composite Panels be installed on building exteriors?

A: Brush Aluminium Composite Panels are lightweight and easy to handle, simplifying installation. They can be fixed using traditional brackets and support frames directly onto substrates, such as concrete, metal, or wood. The panels are delivered with a protective film and are dimensionally consistent, aiding a seamless installation process by experienced professionals.Q: What are the key benefits of the Class B1 fire rating for these panels?

A: A Class B1 fire rating signifies that the panels are flame-retardant and meet strict safety standards for construction materials. This enhances building safety by reducing fire risk and allowing use in both residential and commercial settings where fire-resistance is a priority.Q: When should I choose a customized brush finish for my project?

A: Choosing a customized brush finish is ideal when you need to match specific aesthetic requirements or corporate branding. Its recommended for projects needing a unique visual effect, while still benefiting from the panels durability and weather resistance.Q: Where are these panels commonly used?

A: These aluminium composite panels are widely used in building cladding, architectural faades, signage, and both interior and exterior decoration. Their durability and range of finishes make them suitable for commercial, industrial, and residential projects across India.Q: What process ensures the durability of the panels surface?

A: The panels undergo PVDF (Polyvinylidene Fluoride) coating, which delivers a robust surface resistant to weather, corrosion, and UV exposure. This process guarantees the panels retain their appearance and structural integrity over time, even in demanding environments.Q: How does the panels thermal and sound properties benefit a building?

A: With a thermal conductivity of 0.45 W/m.K and sound absorption of 23 dB, the panels contribute to effective insulation, reducing both heat transfer and external noise. This enhances energy efficiency and comfort within buildings.Q: What makes the core material of these panels safe and eco-friendly?

A: The core consists of non-toxic polyethylene, which is free of harmful substances. It helps ensure that the panels are safe for various environments and contribute to overall building sustainability, meeting environmental and health standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

Customized Aluminum Composite Panel

Price 70 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Protective Film : PE Film on Surface

Feature : Other, Weather Resistant, Durable, Lightweight, Corrosion Resistant

Application : Exterior

Surface Treatment : PVDF Coated

Nano PVDF Aluminium Composite Panel

Price 130 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Protective Film : PE Protective Film on Surface

Feature : Other, Weather Resistant, UV Resistant, Antistatic, Antipollution, Selfcleaning

Application : Exterior

Surface Treatment : PVDF Coated

Timber Walnut Aluminum Composite Panel

Price 120 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Protective Film : PE or Protective Film on Top Surface

Feature : Other, Fireproof, Lightweight, UV Resistant

Application : Exterior

Surface Treatment : PVDF Coated

Wood Grain Aluminum Composite Panel

Price 65 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Protective Film : PE coated on surface

Feature : Other, Lightweight, Weatherproof, Corrosion Resistant, Fireproof

Application : Exterior

Surface Treatment : PVDF Coated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free