Customized Aluminum Composite Panel

Price 70 INR/ Square Foot

Customized Aluminum Composite Panel Specification

- Usage

- Building Cladding, Facade, Signage, Decoration

- Feature

- Weather Resistant, Durable, Lightweight, Corrosion Resistant

- Protective Film

- PE Film on Surface

- Material

- Aluminum

- Dimension (L*W*H)

- 1220 mm x 2440 mm x Custom (As per order)

- Surface Treatment

- PVDF Coated

- Coating Thickness

- 25 micron (PVDF)

- Panel Thickness

- 3mm, 4mm, 5mm, 6mm (Customizable)

- Aluminum Thickness

- 0.21mm, 0.3mm, 0.4mm, 0.5mm (Customizable)

- Tensile Strength

- 130 MPa

- Yield Strength

- 110 MPa

- Color

- Customized (Solid, Metallic, Wooden, Marble, Mirror, etc.)

- Application

- Exterior

- Thermal Expansion

- 2.4 mm/m at 100°C

- Finish Options

- Glossy, Matte, Brushed, Mirror

- Standard Size

- 1220mm x 2440mm / 1500mm x 3050mm (Others available)

- Sound Insulation

- Up to 25 dB (4mm panel)

- Core Material

- Non-toxic LDPE/Fire-retardant core

- Fire Rating

- Class B1 or A2 (EN13501-1)

- Adhesive

- High-Quality Adhesive for Strong Bonding

- Water Absorption

- < 0.01%

- Weight

- Approx. 5.5 kg/m² (4mm panel)

Customized Aluminum Composite Panel Trade Information

- Minimum Order Quantity

- 160 Square Foots

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 5-7 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Asia, Central America, Africa

- Main Domestic Market

- All India

About Customized Aluminum Composite Panel

Product Details:

| Squareness | + 5.0 mm |

| Standard Length | 3660 mm |

| Standard Width | 120 mm |

| Material | Aluminium |

| Brand | Alstrom International Private Limited |

| Model Name/Number | ACP-09 |

| Thickness | 3 mm |

| Shape | Rectangular |

| Finishing | PVDF Coating |

| Function | Mould-Proof |

| Usage/Application | Exterior |

Exceptional Fire Safety and Durability

Our aluminum composite panels adhere to strict fire safety standards (Class B1/A2, EN13501-1), making them suitable for high-performance building cladding and facades. The PVDF coating ensures protection against harsh weather conditions, while the robust tensile (130 MPa) and yield strengths (110 MPa) guarantee long-lasting durability. Designed to resist corrosion and minimize water absorption, these panels provide reliable safety and structural integrity in all climates.

Versatile Customization and Application

Choose from a range of panel thicknesses, aluminum skins, and surface finishes to match your projects aesthetic and functional needs. Standard sizes include 1220mm x 2440mm and 1500mm x 3050mm, with custom dimensions and colors available on request. Perfect for use as exterior cladding, architectural facades, signage, and decorative panels, our ACPs offer flexible solutions for architects, builders, and signmakers.

FAQs of Customized Aluminum Composite Panel:

Q: How are the fire ratings of Class B1 and A2 determined for these aluminum composite panels?

A: The fire ratings for these panels are certified according to the EN13501-1 standard. Class B1 and A2 indicate high levels of fire resistance, making the panels suitable for building applications that require stringent fire safety compliance.Q: What core materials are used in the panel, and how do they enhance safety?

A: Our panels use either a non-toxic LDPE core or a specially engineered fire-retardant core. These materials help limit fire spread and produce less smoke, prioritizing occupant safety during fire events.Q: When should PVDF-coated ACPs be chosen for a project?

A: PVDF-coated panels are ideal for exterior applications and projects requiring superior weather and corrosion resistance, such as building facades, cladding, and outdoor signage. The PVDF coating extends panel lifespan and maintains its appearance over time.Q: Where can customized aluminum composite panels be applied most effectively?

A: These panels are extensively used in building cladding, architectural facades, exterior signage, interior decoration, and protective wall linings. Their lightweight, strength, and design flexibility make them suitable for both residential and commercial environments.Q: What is the process for ordering customized sizes or colors?

A: Simply specify your required dimensions, panel thickness, aluminum skin thickness, finish, and color preferences when placing the order. We offer tailored manufacturing to meet your projects unique requirements, including a variety of solid, metallic, wooden, marble, and mirror effects.Q: How does sound insulation work in these ACPs, and what benefit does it provide?

A: Thanks to their multi-layered structure, our 4mm panels offer up to 25 dB of sound insulation, reducing external noise for occupants. This feature is particularly beneficial in urban buildings, hospitals, schools, and commercial complexes needing quieter environments.Q: What are the key benefits of using these panels for construction and decoration?

A: The panels combine fire safety, durability, weather resistance, and lightweight design. Their customizable finishes and colors provide design flexibility, while strong bonding adhesives and protective films ensure easy installation and lasting surface quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

Brush Butler Finish ACP

Price 70 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Feature : Other, Weather Proof, Rust Proof

Usage : Other, Interior & Exterior Cladding

Application : Showrooms, Lift, Jewelry stores

Material : Aluminum

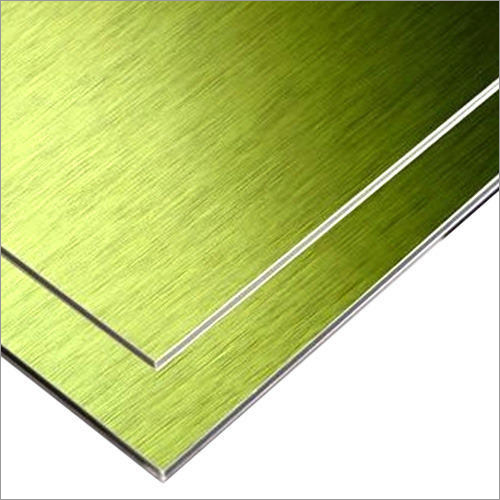

Brush Aluminium Composite Panel

Price 70 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Feature : Other, Weather Resistant, Corrosion Resistant, Easy to Install

Usage : Other, Building Cladding, Signage, Interior and Exterior Decoration

Application : Exterior

Material : Aluminum

White Aluminium Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Feature : Other, Weather resistant, Anticorrosive, UV resistant

Usage : Other, Cladding, Facade, Signage, Wall Panel, Decoration

Application : Exterior

Material : Aluminum

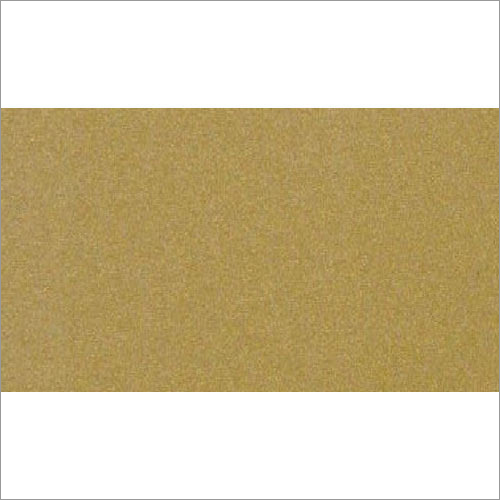

Gold Aluminium Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Feature : Other, Weather Resistant, Lightweight, Easy Fabrication

Usage : Other, Wall Cladding, Interior Decoration, Signage

Application : Interior

Material : Aluminum

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS