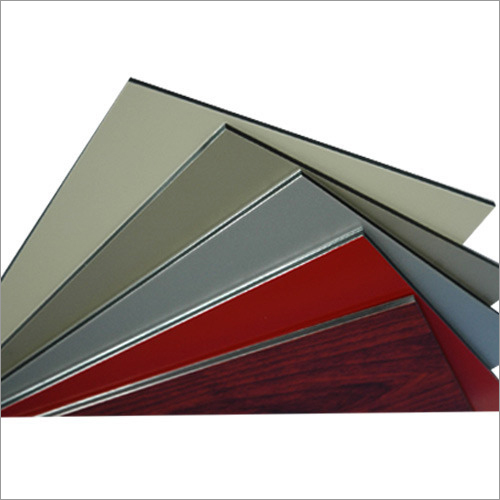

3 mm PVDF Aluminum Composite Panel

Price 70 INR/ Square Foot

3 mm PVDF Aluminum Composite Panel Specification

- Feature

- Weather Resistant, High Strength, Fire Retardant

- Protective Film

- Yes, removable protective film on surface

- Usage

- Curtain Wall, Facade, Exterior Cladding

- Material

- Aluminum

- Dimension (L*W*H)

- 1220 mm x 2440 mm x 3 mm

- Surface Treatment

- PVDF Coated

- Coating Thickness

- 25 microns (PVDF)

- Panel Thickness

- 3 mm

- Aluminum Thickness

- 0.21 mm

- Tensile Strength

- 55 MPa

- Yield Strength

- 120 MPa

- Color

- Customizable (Standard: White, Silver, Grey)

- Application

- Exterior

- Temperature Range

- -50C to +80C

- Gloss Level

- 30%-40%

- Weather Resistance

- Up to 20 years PVDF durability

- Core Material

- Non-toxic LDPE (Low Density Polyethylene)

- Sound Insulation

- 23 dB

- Thermal Expansion Coefficient

- 2.4 mm/m at 100C

- Panel Weight

- 4.5 kg/m

- Fire Rating

- Class B1/FR

- Water Absorption

- 0.01%

3 mm PVDF Aluminum Composite Panel Trade Information

- Minimum Order Quantity

- 160 Square Foots

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 4-5 Days

- Main Export Market(s)

- South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Australia, Africa

- Main Domestic Market

- All India

About 3 mm PVDF Aluminum Composite Panel

Product Details:

| Chemical Resistance | 5%HCL |

| Coating Thickness | 25 to 28 um |

| Humidity Resistance | 3000hrs, 100%RH, 100deg F |

| Panel Peeling Strength | 7 N/mm for 4mm panel with 0.5mm aluminium |

| Salt Spray Resistance | 3000hrs, 5% salt |

| Surface Treatment | PVDF Coating |

| Usage/Application | Exterior |

| Material | Aluminum |

| Thickness | 3 mm |

Superior Durability for Outdoor Applications

Engineered to withstand even the most challenging environments, the 3 mm PVDF Aluminum Composite Panel ensures up to 20 years of performance. Its fire retardant construction, high weather resistance, and strength make it ideal for Indias diverse climate, while its removable protective film prevents scratches during installation.

Advanced Performance and Safety Features

This panels Class B1/FR fire rating, combined with low water absorption ( 0.01%) and outstanding thermal expansion control, ensures reliability and safety in exterior cladding. The PVDF coating not only enhances durability but also provides an attractive gloss level of 30%-40% for a modern aesthetic.

Customizable Solutions for Modern Architecture

With customizable color options (standard: white, silver, grey) and dimensions of 1220 mm x 2440 mm x 3 mm, designers and builders can achieve precise aesthetic and functional goals. Its high tensile and yield strength offer architectural flexibility without compromising on protection or appearance.

FAQs of 3 mm PVDF Aluminum Composite Panel:

Q: How does the 3 mm PVDF Aluminum Composite Panel perform in extreme weather conditions?

A: With a temperature range from -50C to +80C and up to 20 years of PVDF coating durability, this panel is highly resistant to weathering, making it suitable for use in harsh and variable climates commonly found across India.Q: What is the installation process for these panels on building exteriors?

A: The panels are installed by securing them onto structural frameworks, often using mechanical fasteners. The removable protective film should be left on during handling and installation to avoid surface damage, and it can be peeled away once installation is complete.Q: Where can the 3 mm PVDF Aluminum Composite Panel be used most effectively?

A: This panel is optimal for exterior cladding projects such as curtain walls and facades. Its durability, fire retardancy, and aesthetic flexibility make it particularly well-suited for modern commercial buildings and high-rise structures.Q: What benefits does the Class B1/FR fire rating provide?

A: A Class B1/FR fire rating ensures enhanced flame resistance, providing greater safety for building occupants and compliance with stringent fire safety regulations, especially important for public and commercial buildings.Q: Can the color and gloss level of the panels be customized?

A: Yes, the panels are available in customizable colors, with standard options being white, silver, and grey. The surface gloss level ranges between 30% and 40%, offering an attractive and consistent finish.Q: What materials are used in the panels construction and why?

A: The composite panel features PVDF-coated aluminum for weather and UV resistance, combined with a non-toxic LDPE core to provide lightness, impact resistance, and fire retardancy, ensuring a balanced performance for exterior applications.Q: How does the panel support sound insulation and structural strength?

A: With a sound insulation rating of 23 dB and high tensile strength ( 55 MPa), the panel not only helps in reducing external noise but also provides excellent structural integrity, making it a robust solution for demanding building projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

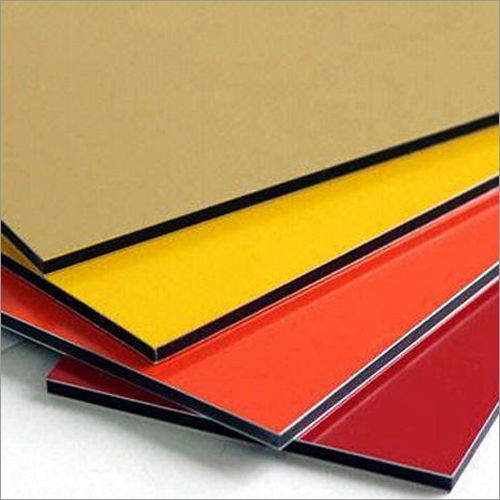

ATM Polyester Aluminum Composite Panel

Price 53 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Yield Strength : 110 MPa

Color : Multiple Colors Available

Usage : Other, Cladding, Facade, Signage, Curtain Walls

Protective Film : Transparent PE Film, Removable

Fireproof Aluminum Composite Panel

Price 100 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Yield Strength : 46 MPa

Color : Multiple colors available

Usage : Other, Exterior & Interior Cladding

Protective Film : PE Film (Removable)

Brush Butler Finish ACP

Price 70 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Yield Strength : > 55 MPa

Color : Silver, Champagne, Gold

Usage : Other, Interior & Exterior Cladding

Protective Film : Yes, removable PE film

Blue Aluminium Panel Sheet

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Yield Strength : 70 MPa

Color : Blue

Usage : Other, Cladding, Facade, Signage, Decoration

Protective Film : Yes, PE Protective Film

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free