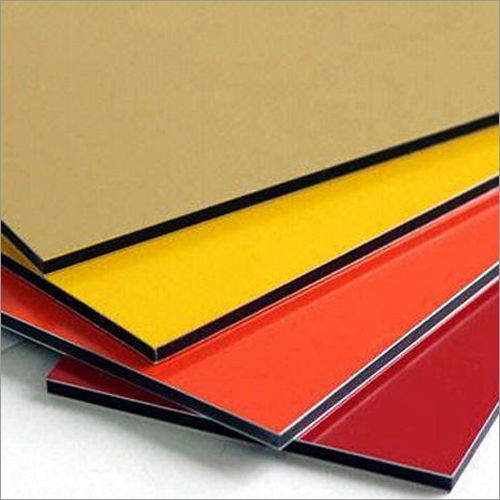

Fireproof Aluminum Composite Panel

Price 100 INR/ Square Foot

Fireproof Aluminum Composite Panel Specification

- Usage

- Exterior & Interior Cladding

- Protective Film

- PE Film (Removable)

- Feature

- Fireproof, Lightweight, Durable

- Material

- Aluminum

- Dimension (L*W*H)

- 1220 mm x 2440 mm x (standard thickness)

- Surface Treatment

- PVDF/PE Coated

- Coating Thickness

- 25 microns (PVDF/Polyester)

- Panel Thickness

- 4 mm (Standard)

- Aluminum Thickness

- 0.50 mm

- Tensile Strength

- 53 MPa

- Yield Strength

- 46 MPa

- Color

- Multiple colors available

- Application

- Office,Shopping Mall

- Fire Rating

- B1 or A2 grade

- Standard Length

- 2440 mm, 3050 mm

- Standard Width

- 1220 mm, 1500 mm

- Weight

- 7.5 kg/m (approx.)

- Water Absorption

- 0.01%

- Weather Resistance

- UV resistant, anti-corrosion

- Temperature Resistance

- -50C to +80C

- Core Material

- Fire-retardant mineral core

- Peel Strength

- 7 N/mm

- Bending Strength

- 100 MPa

Fireproof Aluminum Composite Panel Trade Information

- Minimum Order Quantity

- 160 Square Foots

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 4-5 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Central America

- Main Domestic Market

- All India

About Fireproof Aluminum Composite Panel

Product Details:

| Material | Aluminium |

| Brand | Alstrom International Private Limited |

| Composite Panel Type | Marble Wooden |

| Thickness | 6 mm |

| Shape | Rectangular |

| Finishing | Powder Coated |

| Function | Anti-Static |

| Usage/Application | Office,Shopping Mall |

Advanced Fireproofing for Safety

This panel incorporates a specialized fire-retardant mineral core, achieving a prestigious B1 or A2 fire rating. These specifications ensure enhanced safety by significantly reducing flammability and smoke release. Suitable for public and commercial spaces, it provides crucial protection in high-occupancy buildings without compromising on durability or design flexibility.

Engineered for Durability and Low Maintenance

The PVDF/PE-coated aluminum surfaces resist UV light, moisture, and corrosion, expanding the panels longevity in demanding environments. Its robust structure, boasting superior bending and tensile properties, minimizes maintenance needs. The removable PE protective film ensures the surface remains pristine throughout transportation and installation.

Versatility in Design and Application

Available in standard widths and lengths with a range of colors, this panel adapts easily to both exterior and interior cladding. It is light yet strong (approximately 7.5 kg/m), simplifying handling and installation. Ideal for offices, shopping malls, and commercial developments, the product meets modern architectural demands for aesthetic flexibility and enduring performance.

FAQs of Fireproof Aluminum Composite Panel:

Q: How does the fire-retardant mineral core enhance safety in aluminum composite panels?

A: The fire-retardant mineral core significantly reduces the panels combustibility, enabling it to achieve a B1 or A2 fire rating. This structure limits smoke and flame spread, providing added protection to buildings such as offices and shopping malls where safety standards are crucial.Q: What environments and applications are best suited for these panels?

A: These fireproof aluminum composite panels are ideal for both interior and exterior cladding in offices, shopping malls, and commercial properties. Their robust weather resistance, UV protection, and anti-corrosive features also make them suitable for areas exposed to harsh outdoor conditions.Q: When should I choose a panel with a PVDF coating versus a polyester coating?

A: PVDF coatings are recommended for exterior use due to their superior resistance to weathering, UV rays, and pollution. Polyester coatings, while durable, are best suited for interior applications or shaded areas where environmental exposure is less intense.Q: Where are your panels sourced, and do you provide international services?

A: We operate as a manufacturer, distributor, exporter, importer, supplier, trader, and service provider based in India. Our products are available for both domestic and international markets, ensuring broad accessibility and support.Q: What is the process for installing these aluminum composite panels?

A: Installation typically involves fixing the lightweight panels to a prepared structural framework using standard mechanical fasteners or adhesive systems. The removable PE protective film safeguards the decorative surface during transportation and mounting, ensuring a flawless finish.Q: How do the panels perform in terms of strength and durability?

A: With a bending strength of at least 100 MPa, tensile strength of at least 53 MPa, and yield strength of at least 46 MPa, the panels provide robust structural integrity. Their low water absorption and high peel strength contribute further to their long-term durability and reliability.Q: What are the benefits of using lightweight aluminum composite panels?

A: Weighing approximately 7.5 kg/m, these panels are easier and quicker to handle and install compared to traditional cladding materials. Their lightweight nature reduces structural load, facilitates transportation, and can help lower labor and installation costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

Gold Aluminium Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Coating Thickness : 25 microns (PVDF)

Material : Aluminum

Color : Gold

Surface Treatment : PVDF Coated

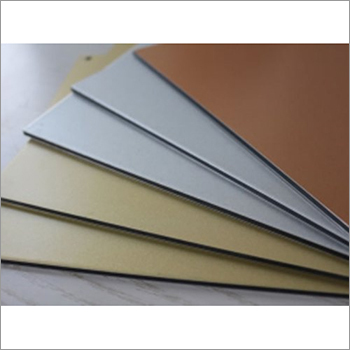

Brush Butler Finish ACP

Price 70 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Coating Thickness : 25 micron (PVDF/Polyester)

Material : Aluminum

Color : Silver, Champagne, Gold

Surface Treatment : Other, Brushed Finish

Red Aluminum Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Coating Thickness : 25 micron

Material : Aluminum

Color : Red

Surface Treatment : PVDF Coated

PVDF Aluminum Composite Panel

Price 75 INR / Square Foot

Minimum Order Quantity : 01 Square Foot

Coating Thickness : 25 micron (PVDF)

Material : Aluminum

Color : Silver Grey, Other colors available

Surface Treatment : PVDF Coated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS