PVDF Aluminum Composite Panel

Price 75 INR/ Square Foot

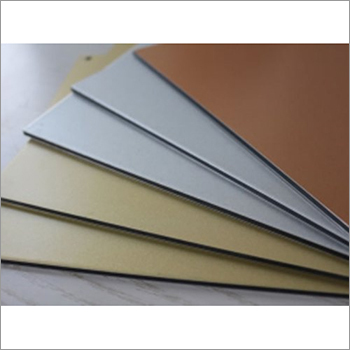

PVDF Aluminum Composite Panel Specification

- Protective Film

- PE Coated Protective Film on Front Surface

- Feature

- Weather Resistant, Durable, UV Resistant

- Usage

- Cladding, Facade, Signage

- Material

- Aluminum

- Dimension (L*W*H)

- 1220 mm x 2440 mm x 4 mm

- Surface Treatment

- PVDF Coated

- Coating Thickness

- 25 micron (PVDF)

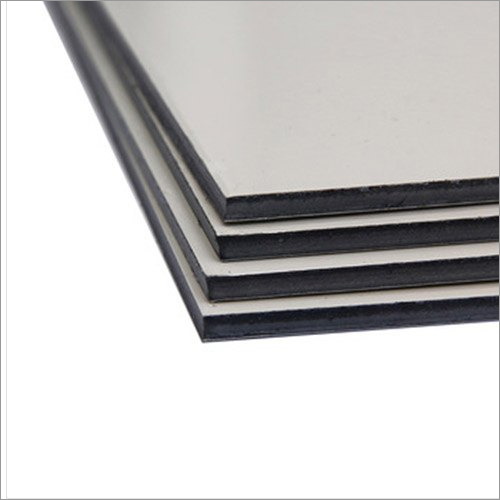

- Panel Thickness

- 4 mm

- Aluminum Thickness

- 0.5 mm

- Tensile Strength

- 33 MPa

- Yield Strength

- 44 MPa

- Color

- Silver Grey, Other colors available

- Application

- Exterior

- Adhesion Strength

- > 0.7 N/mm

- Core Material

- Non-Toxic LDPE (Low Density Polyethylene)

- Weight

- 5.5 kg/m²

- Edge Bonding

- Excellent, Seamless Joint

- Sound Insulation

- 25 dB Reduction

- Moisture Resistance

- 100%

- Thermal Expansion

- 2.4 mm/m at 100°C

- Surface Finish

- High Gloss / Matte

- Fire Rating

- Class B1 (EN 13501-1)

- Service Temperature Range

- -50°C to +80°C

PVDF Aluminum Composite Panel Trade Information

- Minimum Order Quantity

- 01 Square Foot

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 5-7 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About PVDF Aluminum Composite Panel

Product Details:

| Chemical Resistance | 5% HCL |

| Film Adhesion | ASTM D 3359 |

| Surface Treatment | PVDF Coated |

| Usage/Application | Exterior |

| Material | Aluminum |

| Brand | Alstrom International Private Limited |

| Shape | Rectangular |

| Thickness | 10 mm |

Superior Durability & Safety

Our PVDF Aluminum Composite Panel is engineered to withstand extreme weather, UV radiation, and heavy wear. Featuring a fire-resistant Class B1 LDPE core, it ensures operational safety and enduring quality. The panel exhibits excellent tensile and yield strength, making it a reliable choice for structural and decorative applications exposed to harsh conditions.

Versatile Applications for Modern Architecture

Designed for flexibility, this panel adapts to a broad array of uses including building facades, cladding solutions, signage, and more. Its seamless joint and excellent edge bonding provide a sleek, uninterrupted finish. Together with a selection of color options, it elevates any contemporary architectural design, making it suitable for commercial, residential, and industrial projects alike.

FAQs of PVDF Aluminum Composite Panel:

Q: How does the PVDF Aluminum Composite Panel perform in extreme weather conditions?

A: The PVDF coating and non-toxic LDPE core make this panel highly resistant to moisture, UV rays, and fluctuating temperatures. It maintains structural integrity and appearance within a service temperature range of -50C to +80C, making it ideal for exterior use in various climates.Q: What is the fire safety rating of this composite panel, and why is it important?

A: This panel is rated Class B1 according to EN 13501-1, indicating effective flame retardancy. This fire rating is crucial for enhancing the safety of public and commercial buildings, reducing risks in the event of fire incidents.Q: When should I choose a high gloss versus a matte surface finish?

A: A high gloss finish delivers a vibrant, reflective appearance, ideal for bold facades or signage, while a matte finish offers a subdued, elegant look, reducing glare and hiding minor surface imperfectionsperfect for sophisticated architectural requirements.Q: Where can these panels be installed?

A: PVDF Aluminum Composite Panels are designed primarily for external applications such as building cladding, facades, and outdoor signage. Their resilience to weather and environmental stress makes them suitable for use on commercial, industrial, or residential buildings.Q: What process ensures the panels excellent edge bonding and seamless joint finish?

A: Advanced manufacturing techniques and quality adhesives are used to achieve superior edge bonding, resulting in seamless joints. This ensures a visually appealing surface and enhances durability, preventing water ingress and improving overall lifespan.Q: How does this panel contribute to sound insulation?

A: Thanks to its structure, the panel reduces sound transmission by up to 25 dB. This feature is especially beneficial in noisy urban environments, helping to create more comfortable indoor atmospheres.Q: What are the main benefits of using PVDF Aluminum Composite Panels from this supplier?

A: Clients benefit from long-term durability, exceptional moisture and UV resistance, a variety of color and finish options, and reliable distribution and support throughout India and for export. The panels are lightweight, easy to install, and maintain their appearance for years.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

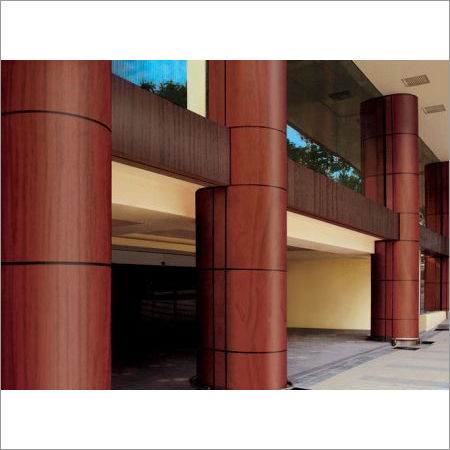

Wooden Finish Aluminum Composite Panel

Price 120 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Color : Wooden Finish

Material : Aluminum

Surface Treatment : PVDF Coated

Usage : Other, Wall Cladding, Facade, Decoration

Gold Aluminium Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Color : Gold

Material : Aluminum

Surface Treatment : PVDF Coated

Usage : Other, Wall Cladding, Interior Decoration, Signage

Mirror Aluminum Composite Panel

Price 85 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Color : Silver mirror, Gold mirror, Copper mirror

Material : Aluminum

Surface Treatment : Mirror

Usage : Other, Wall cladding, Interior decoration, Signage, False ceilings

Nano PVDF Aluminium Composite Panel

Price 130 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Color : Customizable, Standard White/Silver/Grey

Material : Aluminum

Surface Treatment : PVDF Coated

Usage : Other, Exterior Cladding, Curtain Wall, Facade Decoration

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS