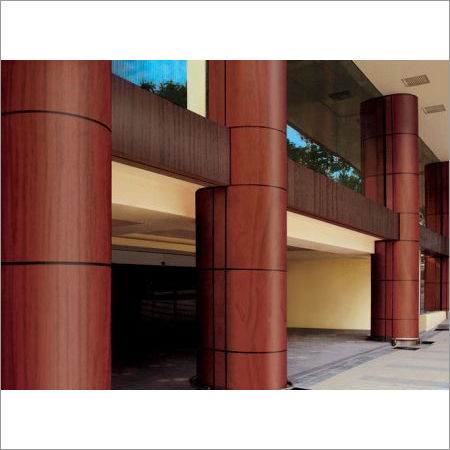

Wooden Finish Aluminum Composite Panel

Price 120 INR/ Square Foot

Wooden Finish Aluminum Composite Panel Specification

- Protective Film

- Double-sided PE protection film

- Feature

- Wooden Finish, Weather Resistant, Durable

- Usage

- Wall Cladding, Facade, Decoration

- Material

- Aluminum

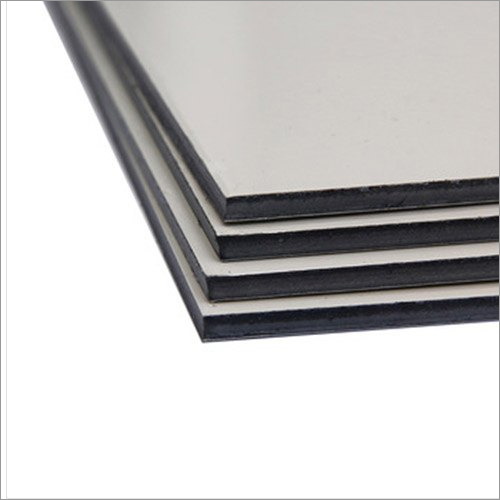

- Dimension (L*W*H)

- 2440 mm x 1220 mm x 4 mm

- Surface Treatment

- PVDF Coated

- Coating Thickness

- 25 micron (PVDF)

- Panel Thickness

- 4 mm

- Aluminum Thickness

- 0.5 mm

- Tensile Strength

- 55 MPa

- Yield Strength

- 33 MPa

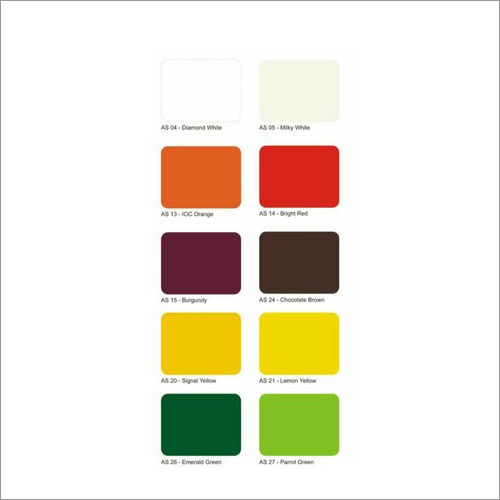

- Color

- Wooden Finish

- Application

- Exterior

Wooden Finish Aluminum Composite Panel Trade Information

- Minimum Order Quantity

- 160 Square Foots

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 5-7 Days

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Wooden Finish Aluminum Composite Panel

Product Details:

| Bow Tolerance | Max 0.5% |

| Length | 4880 mm |

| Length Tolerance | +/-4 mm |

| Squareness Tolerance | Max + 5.0 mm |

| Thickness Tolerance | +/-0.2 mm |

| Width | 1550 mm |

| Appearance | Modern |

| Brand | Alstrom International Private Limited |

| Width Tolerance | +-2 mm |

| Composite Panel Type | Marble Wooden |

| Thickness | 6 mm |

| Surface Treatment | PVDF Coated |

| Weight | 400 gms/sq.ft. |

High-Performance Wooden Finish Panels

Engineered to replicate the elegant appearance of wooden surfaces, these aluminum composite panels are ideal for projects demanding both style and strength. The combination of a non-toxic LDPE core and advanced PVDF coating safeguards against harsh weather, UV exposure, and everyday impacts. Their lightweight nature simplifies installation, making them suitable for large-scale architectural and decorative applications.

Durability Meets Aesthetics

With a surface hardness of 3H and fire ratings up to A2 Grade, these panels offer dependable protection while maintaining their visual appeal. The 25-micron PVDF coating and 0.5 mm aluminum layer ensure longevity, making them an outstanding choice for commercial and residential buildings alike.

FAQs of Wooden Finish Aluminum Composite Panel:

Q: How are Wooden Finish Aluminum Composite Panels installed in exterior applications?

A: These panels are typically installed using a subframe or wall bracket system, ensuring secure mounting to building exteriors. Their dimensions and light weight (5.6 kg/m) simplify handling and enable fast, efficient installation for wall cladding and facade projects.Q: What benefits do Wooden Finish Aluminum Composite Panels offer over natural wood for building facades?

A: Unlike natural wood, these panels provide superior fire resistance (B1/A2 grade), minimal water absorption ( 0.01%), and exceptional UV/weather resistance. They require less maintenance, are not prone to warping or rot, and deliver a consistent wooden appearance.Q: When should you choose a panel with A2 fire rating over B1 for your project?

A: A2-rated panels are recommended for areas where enhanced fire safety is critical, such as high-rise facades and buildings with stringent fire code requirements. B1 is suitable for projects with standard fire protection needs.Q: Where can these panels be used besides exterior facades?

A: In addition to building exteriors, these panels are ideal for decorative wall cladding, interior accents, column covers, and commercial settings where a sophisticated wood look combined with durability is desired.Q: What is the process for maintaining the Wooden Finish Aluminum Composite Panels?

A: Routine cleaning with mild soap and water is sufficient due to their PVDF-coated surface. The panels double-sided PE protective film helps prevent scratches during transport and installation, preserving their finish until final handover.Q: How does the panels impact resistance and hardness contribute to its performance?

A: With impact resistance of 1.5 J and surface hardness of 3H, the panels resist dents and scratches from everyday contact, ensuring lasting visual appeal and structural integrity in high-traffic or exposed environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

Solid Aluminium Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Color : Silver, Grey, Custom colors available

Dimension (L*W*H) : 1220 mm x 2440 mm x 3 mm

Surface Treatment : PE Coated

Usage : Other, Wall cladding, Signage, Partitioning

Nano PVDF Aluminium Composite Panel

Price 130 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Color : Customizable, Standard White/Silver/Grey

Dimension (L*W*H) : 1220 mm x 2440 mm x 4 mm

Surface Treatment : PVDF Coated

Usage : Other, Exterior Cladding, Curtain Wall, Facade Decoration

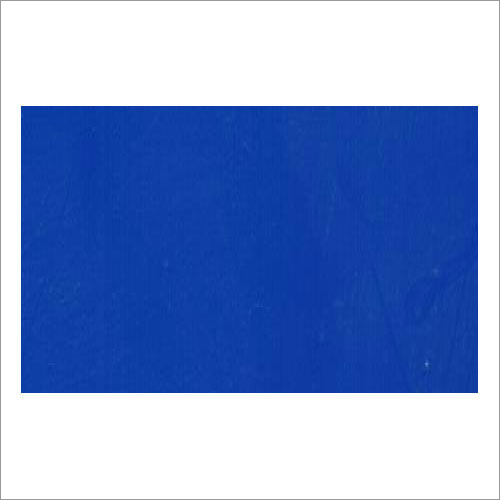

Blue Aluminium Panel Sheet

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Color : Blue

Dimension (L*W*H) : 1220 mm x 2440 mm x Custom Size

Surface Treatment : PVDF Coated

Usage : Other, Cladding, Facade, Signage, Decoration

ATM Polyester Aluminum Composite Panel

Price 53 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Color : Multiple Colors Available

Dimension (L*W*H) : 1220 mm x 2440 mm x 4 mm

Surface Treatment : PVDF Coated

Usage : Other, Cladding, Facade, Signage, Curtain Walls

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free