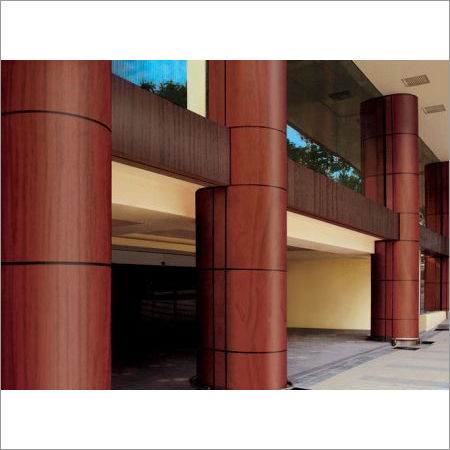

Timber Walnut Aluminum Composite Panel

Price 120 INR/ Square Foot

Timber Walnut Aluminum Composite Panel Specification

- Usage

- Building Cladding, Facades, Signage

- Protective Film

- PE or Protective Film on Top Surface

- Feature

- Fireproof, Lightweight, UV Resistant

- Material

- Aluminum

- Dimension (L*W*H)

- 1220mm x 2440mm x Custom

- Surface Treatment

- PVDF Coated

- Coating Thickness

- 25 microns PVDF

- Panel Thickness

- 3mm, 4mm, 5mm available

- Aluminum Thickness

- 0.15mm to 0.5mm

- Tensile Strength

- >= 240 MPa

- Yield Strength

- >= 170 MPa

- Color

- Timber Walnut

- Application

- Exterior

- Length Tolerance

- 2mm

- Width Tolerance

- 2mm

- Sound Insulation

- High

- Core Material

- Non-Toxic Polyethylene

- Fire Rating

- Class B1 or A2 (depending on core type)

- Installation Method

- Dry Cladding/Mechanical Fixing

- Moisture Resistance

- Superior

- Thermal Expansion Coefficient

- 2.4 x 10^-5 /C

- Density

- 1.5 1.6 g/cm

- Standard Sizes

- 1220mm x 2440mm, custom sizes available

- Weather Resistance

- Excellent with PVDF coating

Timber Walnut Aluminum Composite Panel Trade Information

- Minimum Order Quantity

- 160 Square Foots

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 5-7 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

About Timber Walnut Aluminum Composite Panel

With sincerity and hard work of our professionals, we have carved a niche for ourselves in this domain by providing a durable quality of Timber Walnut Aluminum Composite Panel. It is mostly used in the official and commercial sectors to for wall cladding purpose. This panel is constructed by using high quality aluminium in line with set industry quality norms. Timber Walnut Aluminum Composite Panel comes in a matte finishing smooth texture of walnut timber design.

Product Details:

| Dimensions | 120 mm x 2440 mm |

| Color | Timber Walnut |

| Material | Aluminium |

| Brand | MAGIKBOND |

| Grade | Exterior |

| Composite Panel Type | Marble Wooden |

| Thickness | 3mm- 6mm |

| Shape | Rectangular |

| Finishing | PVDF Coating |

| Usage/Application | Exterior |

Exceptional Durability and Appearance

Timber Walnut Aluminum Composite Panel features a robust PVDF coating for unmatched weather resistance and UV stability, ensuring a lasting timber-like facade that maintains its allure. The high-duty aluminum construction combined with a non-toxic polyethylene core delivers not only striking aesthetics but also excellent mechanical strength and longevity, making it ideal for demanding exterior environments.

Versatile Applications and Easy Installation

Engineered for a range of uses including building facades, exterior wall cladding, and professional signage, these panels are adaptable to multiple design requirements. Their lightweight structure and precise tolerance allow for efficient dry cladding installation, streamlining the construction process and minimizing labor costs while ensuring a seamless, modern look.

FAQs of Timber Walnut Aluminum Composite Panel:

Q: How are Timber Walnut Aluminum Composite Panels installed on building exteriors?

A: These panels are typically mounted using a dry cladding or mechanical fixing method. This process involves securing the panels to the building structure with specialized brackets or frames, eliminating the need for wet adhesives and facilitating quick, clean, and reliable installation.Q: What makes the PVDF coating on Timber Walnut ACPs beneficial for exterior use?

A: The 25-micron PVDF coating provides exceptional protection against weathering, ultraviolet rays, and environmental pollutants. This ensures the panels retain their original timber walnut appearance and structural integrity over time, even in regions with harsh climatic conditions.Q: When should you choose Class B1 or A2 core material for fire safety?

A: Selection between Class B1 and A2 core materials depends on your projects fire safety regulations. Class A2 offers a higher level of non-combustibility, making it suitable for high-rise and critical safety applications, while Class B1 is ideal for most commercial and residential buildings requiring standard fire resistance.Q: Where are Timber Walnut Aluminum Composite Panels commonly applied?

A: These panels are widely used in the cladding of building facades, wall partitions, outdoor signage, and other architectural applications requiring a natural wood look with the durability of aluminum and advanced fire and moisture resistance.Q: What is the process for ordering custom sizes or thicknesses of these panels?

A: To order customized panels, you can consult with the distributor, manufacturer, or supplier with your specific size, thickness, and color requirements. After confirming technical specifications, your order will be processed for tailored production, ensuring a perfect fit for your projects design.Q: How do Timber Walnut ACPs improve sound insulation and building energy efficiency?

A: The composite structure, high-density core, and robust surface material provide high sound insulation and reduce thermal expansion. This contributes to quieter interiors and minimizes heat transference, leading to enhanced energy efficiency for modern buildings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

Wooden Finish Aluminum Composite Panel

Price 120 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Protective Film : Doublesided PE protection film

Feature : Other, Wooden Finish, Weather Resistant, Durable

Material : Aluminum

Panel Thickness : 4 mm

Bright Gold Aluminum Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Protective Film : PE Film, Removable

Feature : Other, Weather Resistant, Lightweight, Durable

Material : Aluminum

Panel Thickness : 4mm

Gold Aluminium Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Protective Film : PE Protective Film on Surface

Feature : Other, Weather Resistant, Lightweight, Easy Fabrication

Material : Aluminum

Panel Thickness : 4 mm

Polyester Aluminium Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Protective Film : Yes, available with logo or plain

Feature : Other, Weather resistant, lightweight, easytoinstall, high durability

Material : Aluminum

Panel Thickness : 3 mm / 4 mm / 6 mm (custom available)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free