Nano Coating Aluminum Composite Panel

Price 130 INR/ Square Foot

Nano Coating Aluminum Composite Panel Specification

- Feature

- Nano Coating, Anti-pollution, Weather Resistant

- Protective Film

- Yes

- Usage

- Wall Cladding, Building Facades

- Material

- Aluminum

- Dimension (L*W*H)

- 1220 mm x 2440 mm x 4 mm

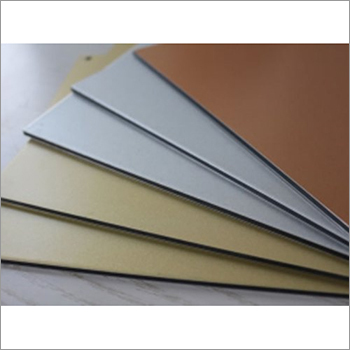

- Surface Treatment

- PVDF Coated

- Coating Thickness

- 25 Micron

- Panel Thickness

- 4 mm

- Aluminum Thickness

- 0.5 mm

- Tensile Strength

- 46 MPa

- Yield Strength

- 44 MPa

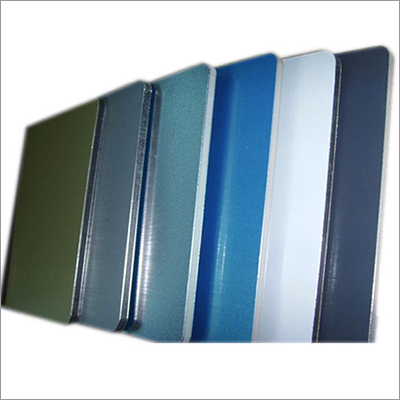

- Color

- Multiple colors available

- Application

- Exterior

- Water Absorption

- 0.01%

- Core Material

- Polyethylene (PE)

- Impact Strength

- >1.8 J/mm

- Peel Strength

- >7 N/mm

- Glossiness

- 30% - 80%

- Fire Rating

- Class B1

- UV Resistance

- Excellent

- Temperature Resistance

- -50C to +80C

Nano Coating Aluminum Composite Panel Trade Information

- Minimum Order Quantity

- 160 Square Foots

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 5-7 Days

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

About Nano Coating Aluminum Composite Panel

Product Details:

| Acid Resistance | 5% HCI, 240 hrs |

| Alkali Resistance | 5% NaOH, 240 hrs |

| Paint Particle | 0.03 micron |

| Pollution Resistance | Dust Hardly Sticks on the Panel |

| Surface Treatment | Nano Coating |

| Material | Aluminium |

| Size | 8 X 4 ft |

| Brand | Alstrom International Private Limited |

| Thickness | 10 mm |

| Shape | Rectangular |

| Usage/Application | Exterior |

Advanced Nano Coating Technology

Our panels are treated with innovative nano coating, which significantly enhances anti-pollution capabilities and extends resistance to harsh weather conditions. This technology protects the panels surface, keeping it clean and vibrant for longer periods, making it highly suitable for modern architectural projects.

Superior Performance for Exterior Applications

Designed specifically for exterior use, the aluminum composite panel offers excellent UV resistance and maintains its structural integrity in temperatures ranging from -50C to +80C. These characteristics ensure long-lasting aesthetics and reliability, even in extreme environmental conditions.

Versatile and Reliable Construction Material

The panels robust physical properties, including high peel strength (>7 N/mm), impact strength (>1.8 J/mm), and low water absorption ( 0.01%), make it a dependable choice for wall cladding and building facades. Its availability in various colors provides flexibility for designers and architects.

FAQs of Nano Coating Aluminum Composite Panel:

Q: How do Nano Coating Aluminum Composite Panels benefit building exteriors?

A: Nano Coating Aluminum Composite Panels enhance building exteriors by providing exceptional resistance to pollution, weather, and UV radiation. Their advanced nano-coated surfaces ensure enduring gloss and color while reducing maintenance needs.Q: What is the primary process for installing these panels on facades?

A: Installation typically involves mounting the panels to a structural framework using specialized fastening systems. The protective film remains on the surface during handling and is removed after installation to maintain the panels pristine condition.Q: When is it advisable to use panels with Class B1 fire rating?

A: Panels with a Class B1 fire rating are suitable for projects that require elevated but not the highest level of fire safety, such as commercial buildings, high-rise residences, and public infrastructure, where enhanced fire resistance is critical.Q: Where can these panels be applied most effectively?

A: Nano Coating Aluminum Composite Panels are most effective for exterior applications, including wall cladding, building facades, and architectural renovations, thanks to their weather-resistant and anti-pollution features.Q: What makes PVDF coating important for these panels?

A: The PVDF coating provides superior protection against UV rays, color fading, and environmental pollutants, significantly extending the panels service life and preserving its appearance.Q: How does the panel perform in extreme temperatures or weather conditions?

A: Engineered for durability, the panel resists temperatures from -50C to +80C without compromising its structural integrity, ensuring long-term performance in diverse climates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

Wood Grain Aluminum Composite Panel

Price 65 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Application : Exterior

Color : Wood Grain Finish

Surface Treatment : PVDF Coated

Usage : Other, Wall Cladding, Facades, Signage, Interior and Exterior Decoration

Gold Aluminium Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Application : Interior

Color : Gold

Surface Treatment : PVDF Coated

Usage : Other, Wall Cladding, Interior Decoration, Signage

PVDF Aluminum Composite Panel

Price 75 INR / Square Foot

Minimum Order Quantity : 01 Square Foot

Application : Exterior

Color : Silver Grey, Other colors available

Surface Treatment : PVDF Coated

Usage : Other, Cladding, Facade, Signage

4 Mm Polyester Aluminium Composite Panel

Price 70 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Application : Exterior

Color : Silver/Grey (custom colors available)

Surface Treatment : Other, Polyester Coating

Usage : Other, Cladding, Facades, Signage

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free